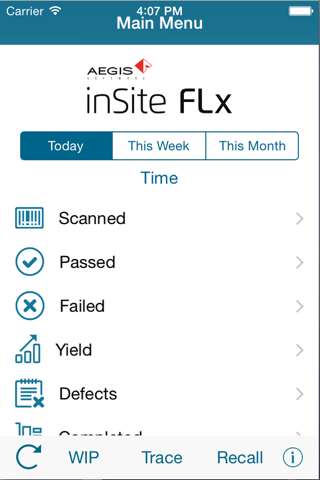

inSite FLx

Aegis inSite FLx (FactoryLogix)

Mobile Visibility Into Your Aegis Manufacturing Operations System

inSite FLx turns your iPad or iPhone into a mobile portal to a vast range of manufacturing and traceability information. Aegis designed the apps for use by engineers, production supervisors, customer program managers, factory management and executive management. It provides quick, easy and mobile access to routinely required and actionable information from their Aegis MOS system.

Key Uses in the Factory:

•Executive Management: Executives who may be unfamiliar with the full Aegis interface can get quick actionable information via the new and improved inSite FLx interface to help guide their factory and to have the business intelligence to make the right decisions.

•Marketing/Sales: Sales and marketing can utilize the simple and powerful mobile interface to provide undeniable proof of the power of the information management within the factory by simply showing the touring customer or prospect the depth and instant nature of information recall in the plant.

•Production Management: Immediate access to WIP status, yield, and problem points.

•Quality Management: Drill into root quality issues and localize them while moving about the factory in real-time.

•Traceability: Respond instantly to traceability requests for a unit, or an emergency reverse lookup to contain a recall.

•Manufacturing and Process Engineering: Gain instant undistorted data about the latest manufacturing issue while walking to the floor and be armed with the data to properly resolve the situation.

Key Features of inSite FLx:

•Forward Traceability: Input a product serial number and instantly recall the product image, the route, materials content with lots, test symptoms, measurements and defects found during production.

•Reverse Traceability: Input a material lot and part number and recall the serialized units into which that lot component was installed.

•Share: Email reverse traceability data directly from the app to assist in the fastest possible recall containment.

•Visualize: Recall the actual product image from the CAD design at the time of manufacture by inputting its serial number.

•Summary Data: From one view, see the scanned quantity, passed quantity, failed quantity, yield, defects and completed units and drill into detailed bar graphs or Paretos.

•Quality Data: Scoping by time, work order, assembly etc, drill into Paretos, to defect types, quantities, and even down to the pin or connection level of a single component.

•WIP Monitor: Drill into the unit quantities at this moment residing at certain work cell or route locations of units within a work order, part numbers, etc.

•Packout Records: See the progress on a particular job and the ship quantities and records.

•Quality: Drill down into the yield and defects by time, work order, and assembly.

System Requirements:

•iOS 10.0 and above operating system on iPad or iPhone

•Aegis Version 8.3 and above MOS system.

•Depending on security settings TCP Port 6062 should be created for inbound rules when using Windows Firewall

•Wifi connection or mobile data connection are required. (IPV6 is not supported)

•Data available via inSite is dependent upon the MOS system modules owned and their deployment within the factory. The application cannot display data the system is not gathering.